90 days...

N0 Payments!

90 days... N0 Payments!

Click to GET STARTED

Click to GET STARTED

90 days...

N0 Payments!

90 days... N0 Payments!

Click to GET STARTED

Click to GET STARTED

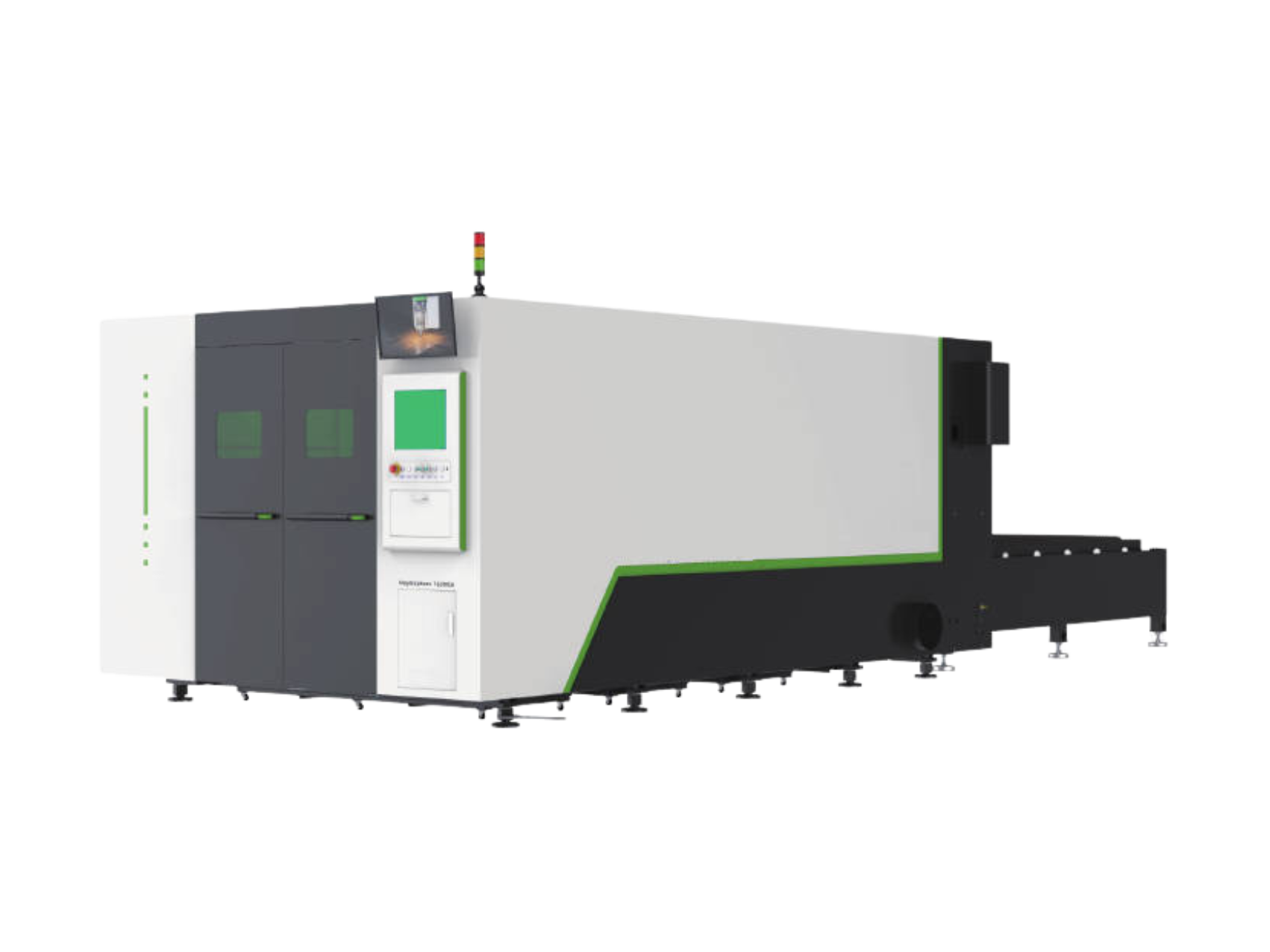

The Lightning 510 DS Fiber laser Dual Shuttle cutting

machine is a laser processing solution that is

professionally used in metal processing. The equipment is

designed with a gantry double drive structure,

which is dual gear rack and dual servo motor

drive system with high-speed arc cutting

function, that can effectively meet the application requirements of metal materials such as

carbon steel, stainless steel, aluminum plate,

galvanized sheet, etc

Scroll down for more information.

Machine Features

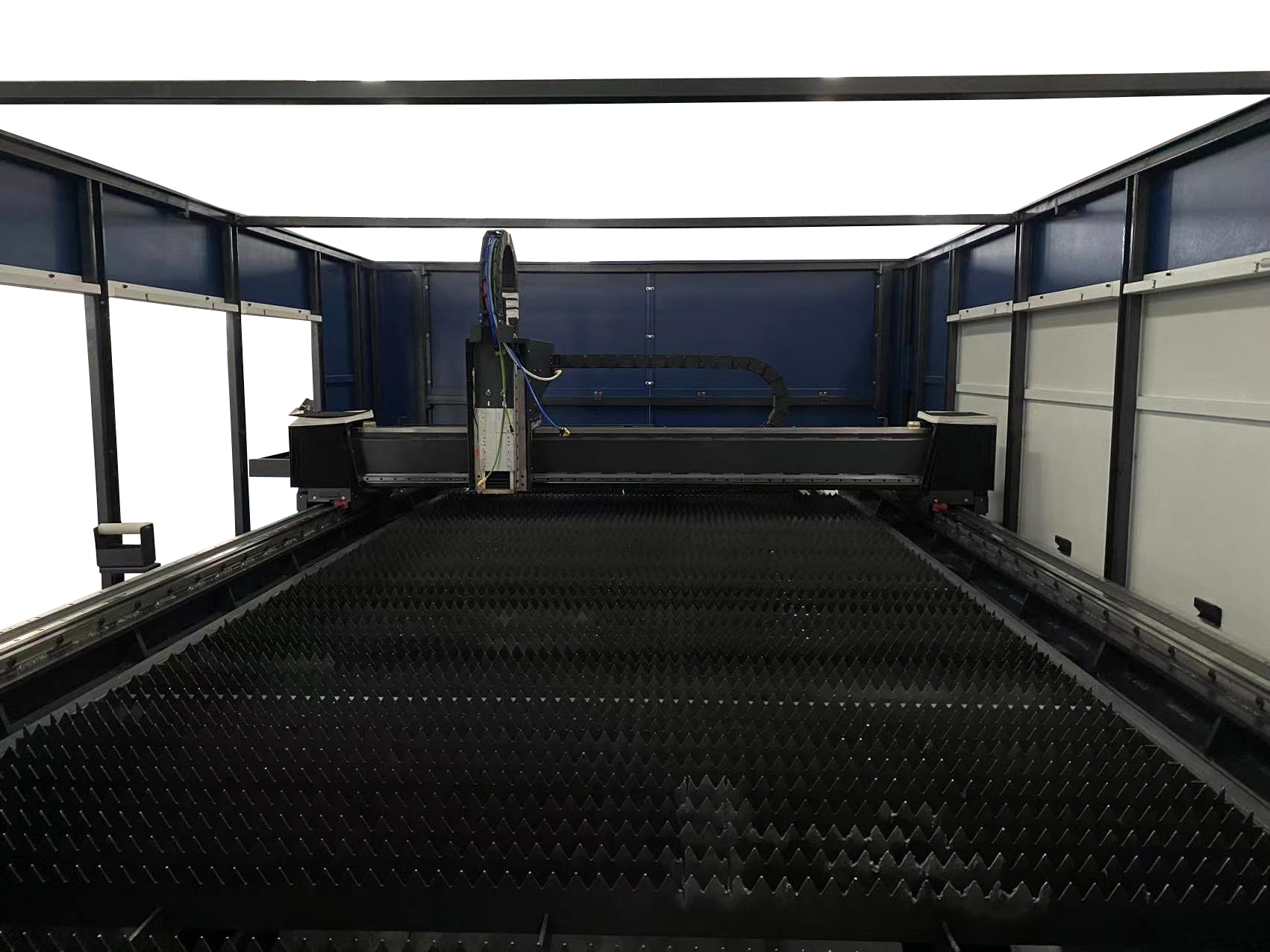

• High Rigidity enhanced aviation aluminum gantry

• Integrated structure design

• Over 6" of standard clearance between bed and gantry

• Reasonable overall layout

• Professional laser cutting software with graphic layout and smart corner smoothing functions, fast piercing and cutting

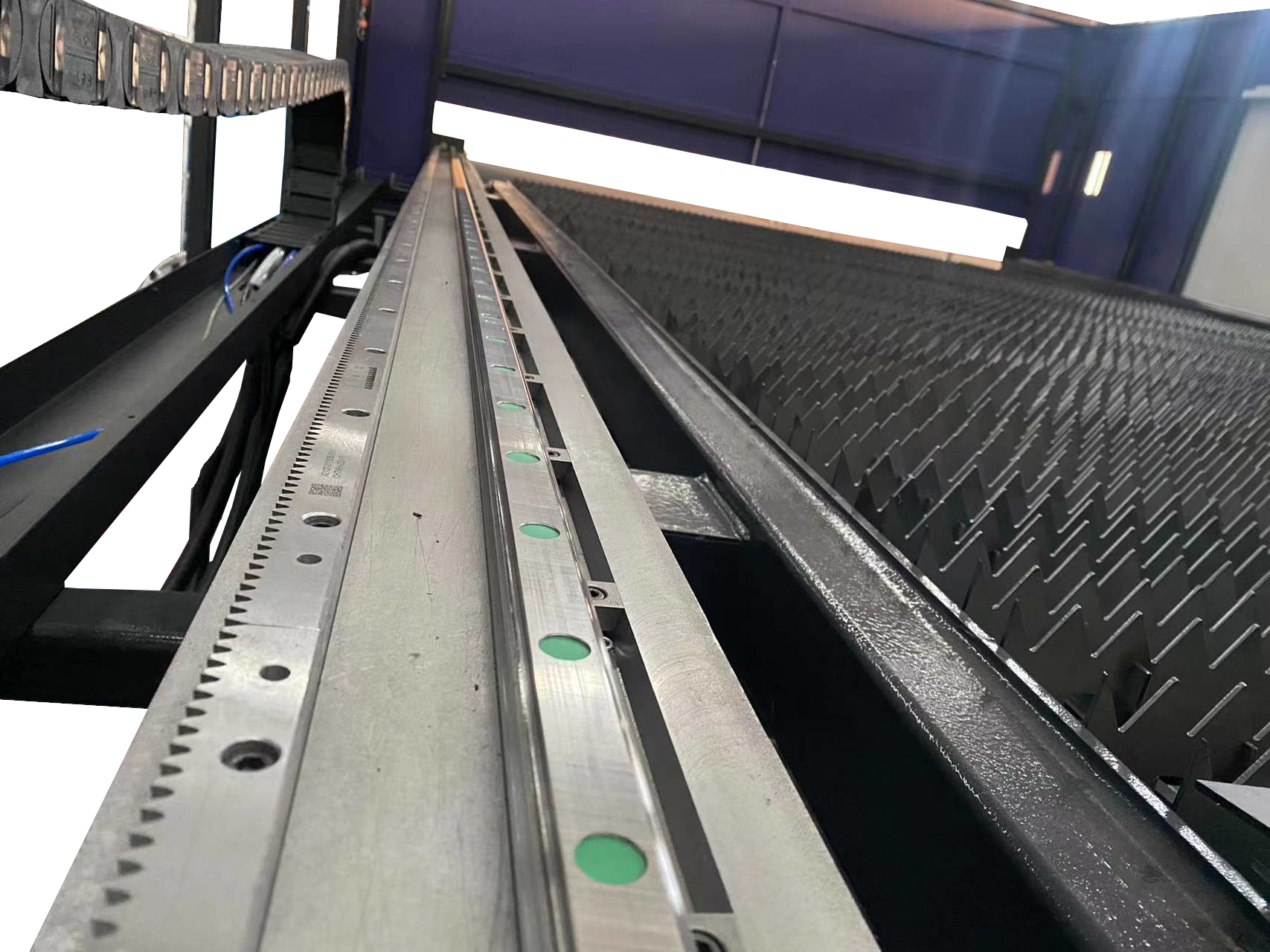

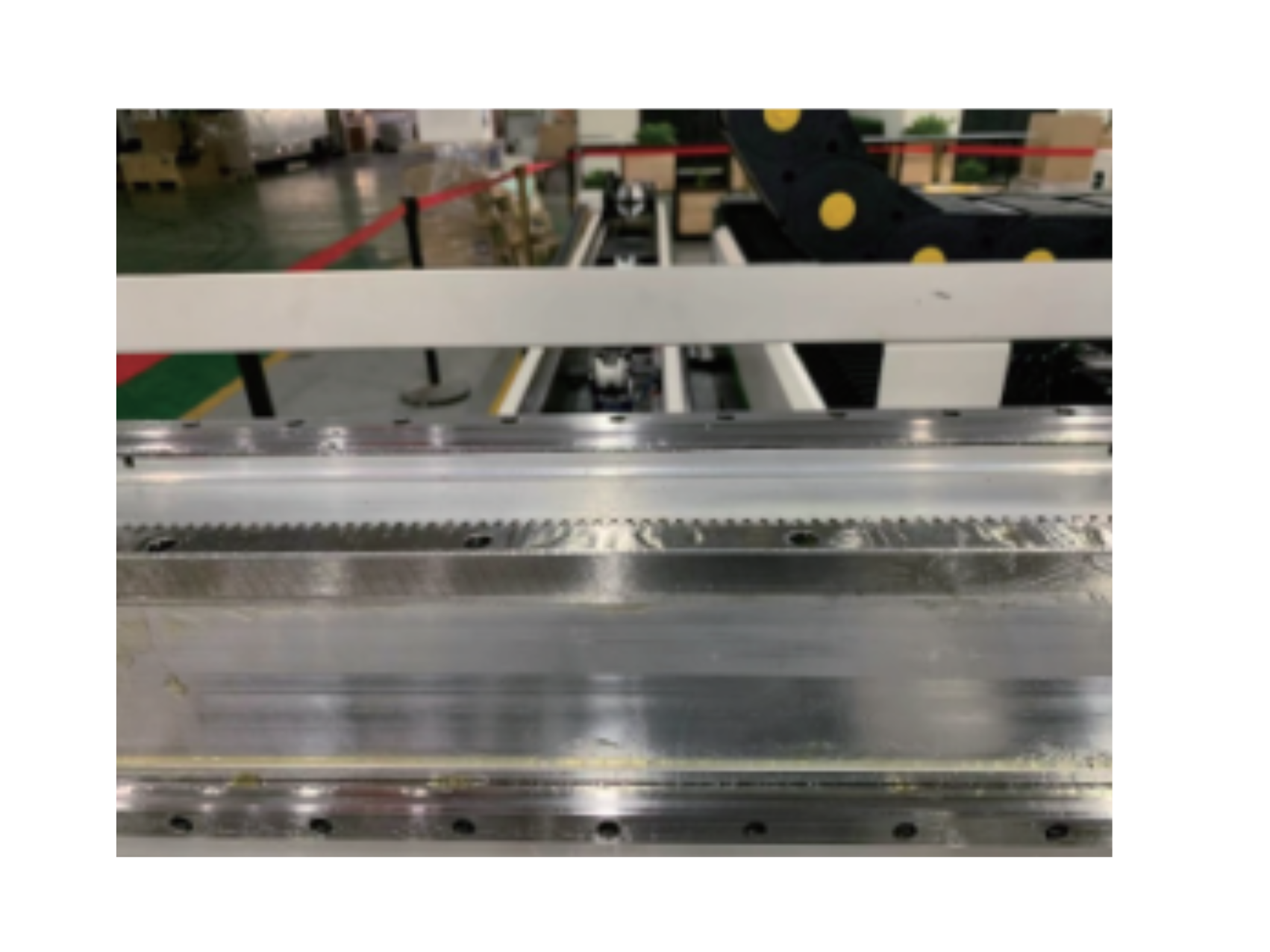

• Rack and pinion drive on X/Y axis provides precise and smooth motion

• Fully enclosed cable track system protects all wires, cables, and hoses

• Fiber laser has better industry leading wall plug efficiency

• Precision linear guide on all axes

• Hand controller is available for easy operation

Machine Specifications

• Working area Multiple Sizes available

• Laser power 1000W~20000W

• Transmission System Sync-dual Servo rack and pinion system

• Positioning speed(MAX) 4700 in/min

• Positioning accuracy ±0.001in

•Repositioning accuracy of clamp ±0.0008in

• Format DXF and NC

• Standard Power Requirements Three phase 480V (other Voltage available upon request

Easy modular Design with easy maintenance.

3 Cover glasses (top, middle and

bottom) to protect collimation & focus lens.

Dual water cooling circuits.

IP65 class dustproof, patented cover glass cover plate. All-around dust

prevention.

Auto focus to reduce human intervention and improve piercing

and cutting efficiency.

Easy modular Design with easy maintenance.

3 Cover glasses (top, middle and

bottom) to protect collimation & focus lens.

Dual water cooling circuits.

IP65 class dustproof, patented cover glass cover plate. All-around dust

prevention.

Auto focus to reduce human intervention and improve piercing

and cutting efficiency.

•Rated to 6kW @ 1um, with D37 lens combo for thick plate cutting.

•Updated version from BM114S with improved design of optics systems and gas circuit.

•Collimation and focusing lenses are both water cooled.

•Compact design to reduce the payload of Z axis.

•35mm Clear aperture which effectively reduces stray beam

interference and guarantee cutting quality and lifespan

•Additional middle cover glass is equipped to prolong lifespan of focus lens

•Air cooling to nozzle which effectively protects the nozzle & ceramic part and extends the

lifespan.

•Auto focus by Yaskawa or AheadTechs Servo.

•Auto focus control via 0-10V or EtherCAT

•4-Color LED lamps to monitor interior status

•Real-time status of cutting head could be accessed at mobile APP or CNC controller.

•USA/Germany/Japan made fused silica raw lens material.

•Optimized optical configuration and smooth

gas circuit

•Optimized X/Y alignment knob to facilitate

beam alignment

•Real-time monitoring to temperature of top/bottom cover glass, focus lens and cavity

•Real-time monitoring to cutting gas pressure

and cavity pressure

•Standard QBH/QD (LLK-D)/G5 interfaces to

work with different fiber lasers

•Auto focus control via 0-10V or EtherCAT

•4-Color LED lamps to monitor interior status

•Real-time status of cutting head could be accessed at mobile APP or CNC controller.

•Real-time monitoring to focus position and ready status of bottom cover glass

•USA/Germany/Japan made fused silica raw lens material. High power rating of lens by 12000W.

•Additional middle cover glass is equipped to prolong lifespan of focus lens

•Optimized optical configuration and smooth

gas circuit

•Optimized X/Y alignment knob to facilitate

beam alignment

•Real-time monitoring to temperature of top/bottom cover glass, focus lens and cavity

•Real-time monitoring to cutting gas pressure

and cavity pressure

•Standard QBH/QD (LLK-D)/G5 interfaces

to work with different fiber lasers

•Auto focus control via 0-10V or EtherCAT

•4-Color LED lamps to monitor interior status

•Real-time status of cutting head could be accessed at mobile APP or CNC controller.

•Real-time monitoring to focus position and ready status of bottom cover glass

•USA/Germany/Japan made fused silica raw lens material.

•Additional middle cover glass is equipped to prolong lifespan of focus lens

•Optimized optical configuration and smooth

gas circuit

•Optimized X/Y alignment knob to facilitate

beam alignment

•Real-time monitoring to temperature of top/bottom cover glass, focus lens and cavity

•Real-time monitoring to cutting gas pressure

and cavity pressure

•Standard QBH/QD/Q+/LOE interfaces to work with different fiber lasers

300W Single Module CW Fiber Laser based on modular design, has excellent beam quality and high stability, which structure is compact and air cooling.The laser can be adjusted continuously,and the beam is transmitted by fiber and QBH connector. The laser is very suitable for system intergration with robot or machine tool, and is widely used for laser cutting, welding, 3D printing on electronics, automobile parts, etc.

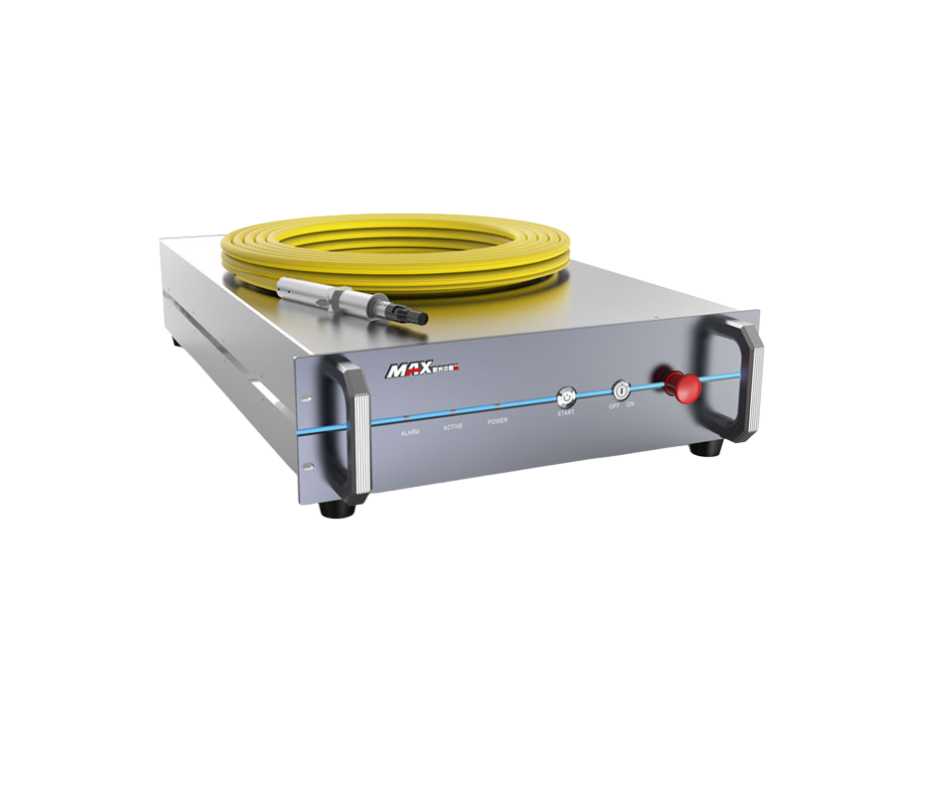

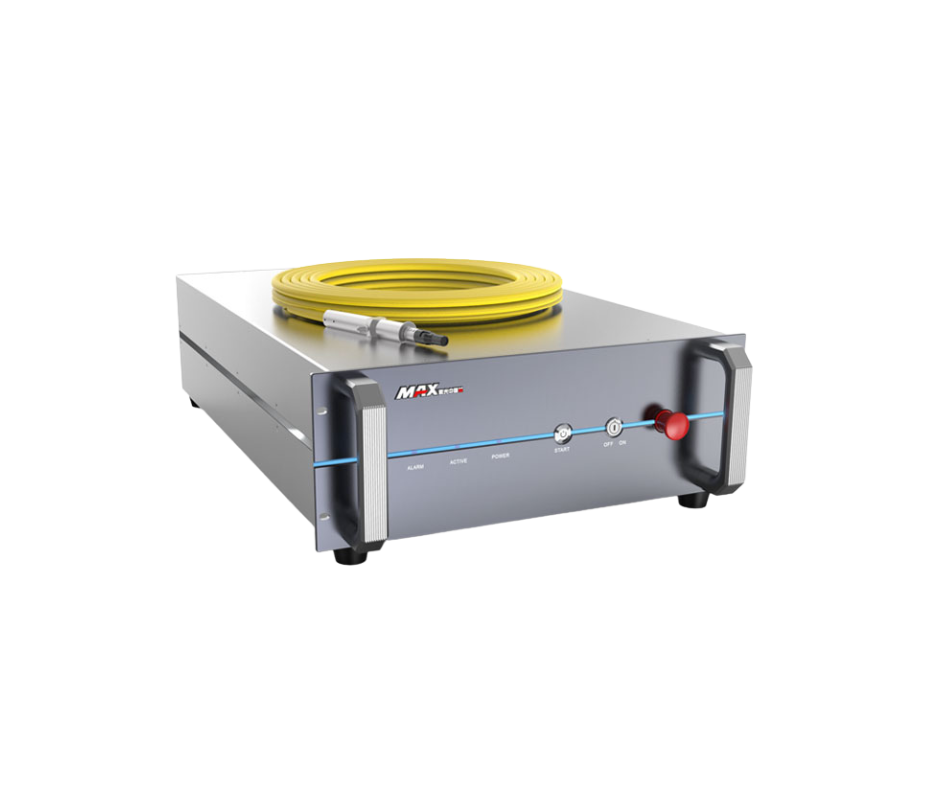

The MFSC 500W series lasers are water-cooled and maintenance-free and with a wall plug efficiency of more than 25% and deliver high efficiency, high reliability and high performance,which can be used for cutting, welding and drilling of metal materials such as stainless steel, carbon steel, aluminum and copper. It is widely used in sheet metal cutting, metal processing, home appliance manufacturing, automobile manufacturing and other fields.

MFSC 1000W-1500W Single Module CW Fiber Laser, based on modular design,has excellent beam quality and high stability, which structure is compact and water-cooling. The laser can be adjusted continuously, and the beam is transmitted be fiber and QBH connector, which is ideal for laser cutting, laser welding, etc . The laser is very suitable for system intergration with robot or machine tool, and is widely used for laser cutting, welding, 3D printing, electronics, automobile parts,aerospace, etc.

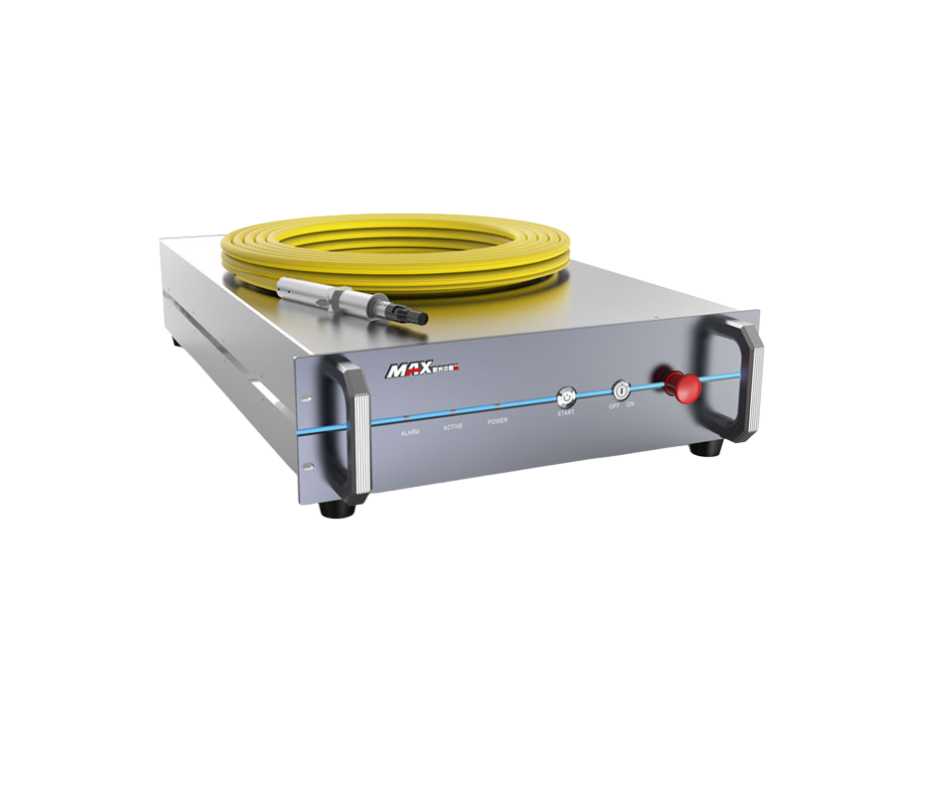

The new generation of Single Module 2000W-3000W Fiber Lasers which combined with high power, compact size, superior beam quality, and high light conversion efficiency. It can meet the requirements of precision processing, 3C product welding and high-reflective material cutting ability are significantly improved. It is suitable for remote processing, high-frequency laser cutting and clean surface cutting. It can be quickly and conveniently integrated into machine tool equipment and large-scale factory automation production line. Product advantages: 1. More reliable and saving power. 2. Easy to maintain. 3. Easy to operate.

Copyright © 2025 Lone Star Cutting Solutions. All Rights Reserved.

Designed, Developed & Hosted by Duncan Multi-Media.